Water is an essential resource for numerous industrial processes. The purity of water used in these processes can significantly impact the quality, safety, and efficiency of the final products. Distilled water, known for its high purity, is crucial in various industries due to its unique properties. This blog explores the benefits and uses of distilled water in different industries in Sri Lanka, highlighting the importance of maintaining water purity in industrial applications.

Understanding Distilled Water

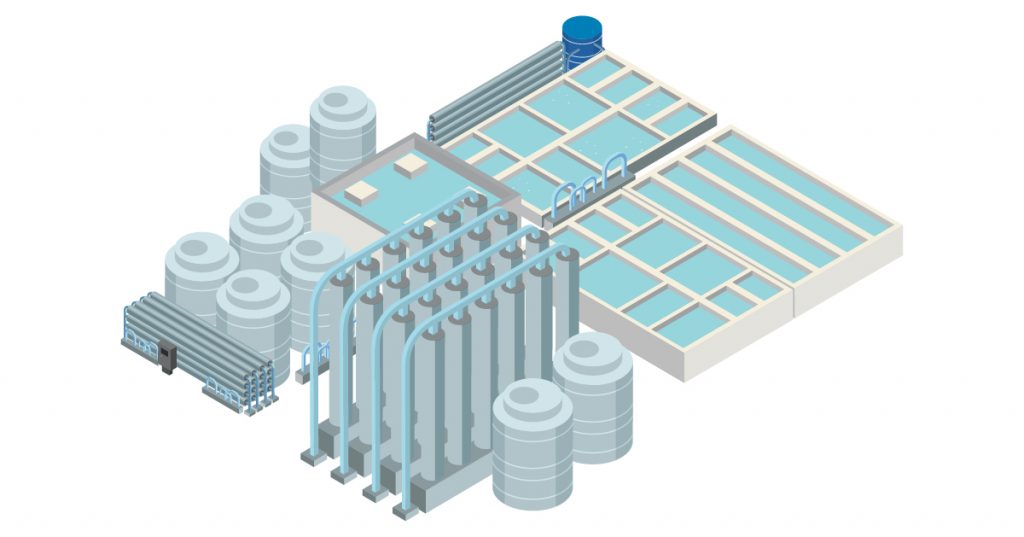

Distilled water is water that has undergone a purification process called distillation. This process involves boiling the water to produce steam and then condensing the steam back into liquid form, leaving impurities behind.

The Process of Water and Steam Distillation

The distillation process begins with heating the water to its boiling point, where it evaporates and forms steam. The steam is then collected and passed through a cooling system, where it condenses back into liquid water. This condensed water, known as distilled water, is free from most impurities present in the original water source. Pure water distillers are devices designed to carry out this process efficiently, ensuring a consistent supply of high-purity water.

Is Distilled Water Safe to Drink?

Distilled water is devoid of minerals, salts, and most biological contaminants, making it chemically and biologically pure. This purity is crucial for applications where the presence of any impurities could interfere with the process or product quality.

What Happens When You Drink Distilled Water?

When you drink distilled water, your body absorbs water that is free from minerals and other contaminants. This can have both benefits and potential drawbacks. The primary benefit is that distilled water does not introduce any additional impurities into your body. However, since it lacks minerals, it may not provide the electrolytes and nutrients found in mineral-rich water.

The Role of Ion Exchange in Enhancing Distilled Water

Complete Cure for the Pharmaceutical Industry’s Need

Ion Exchange brings over six decades of expertise in water and environment management to the pharmaceutical industry, offering tailored solutions for high-purity water treatment, bulk drug purification, and pharmaceutical formulation manufacturing. With state-of-the-art facilities, including a USFDA-compliant pharma resin plant, we provide a full range of specialty resins for various applications. Our advanced effluent treatment and zero liquid discharge solutions ensure compliance with stringent industry norms.

Additionally, we offer comprehensive services in total water management, including high-purity water generation, distribution systems, Lab Q Water Maker, available 24/7, and more.

Comprehensive Solutions for the Food & Beverage Industry

Ion Exchange offers a comprehensive menu of solutions tailored for the food & beverage sector, featuring advanced systems for every process application, including distilled water and pure water distillers. Our complete water treatment and wastewater management solutions are designed to enhance product quality, optimize price performance, and improve operational efficiencies. With specialty chemical treatment programs and 24/7 service support, we help reduce wastage and ensure seamless operations across the entire water treatment circuit, including purification and separation processes.

Distilled Water and Advanced Treatment Systems for Electronics and Semiconductor Industry

In the electronics industry, where the quality of water is paramount, Ion Exchange provides an entire circuit of solutions, ensuring that every drop meets the rigorous demands of manufacturing processes. From large volumes of ultra-pure water required for semiconductors to distilled water for critical applications, Ion Exchange’s comprehensive systems, including pure water distillers, guarantee unmatched purity. Additionally, their wastewater treatment and recycling solutions not only minimize fresh water usage but also promote resource recovery, making them an indispensable partner for the electronics industry.

Turnkey Water Solutions for the Automotive Industry

At Ion Exchange, we address the complete water needs of the entire automotive manufacturing complex with our turnkey solutions. From process water and effluent treatment to recycling, our advanced systems, including distilled water and pure water distillers, ensure the highest quality water for every application. Our vehicle wash effluent treatment effectively removes oils, grease, and other contaminants, making recycled water fit for reuse. This not only reduces the need for freshwater, providing security against shortages but also minimizes waste and ensures compliance with discharge norms.

Ultrapure Water Solutions for Safe Dialysis and Sustainable Healthcare Industry

At Ion Exchange, we are dedicated to providing ultrapure water for kidney dialysis that meets the stringent AAMI standards. Our advanced product, Indion HEMO, utilizes a meticulous multi-stage treatment process to eliminate mineral contaminants and bacterial endotoxins, ensuring patient safety and reducing the risk of adverse reactions such as nausea, vomiting, and muscle weakness during dialysis. We also offer comprehensive wastewater management solutions, promoting sustainability and cost-efficiency by enabling secondary water usage in healthcare facilities. With features like single-pass and double-pass sanitary RO designs, along with customizable pre-treatment options, Indion HEMO is tailored to meet the specific needs of high-purity water for dialysis.

Comprehensive Water Purification Solutions for Laboratory & Diagnostic Industry

Ion Exchange, a pioneer in water treatment in India, offers comprehensive solutions across various sectors such as industries, hotels, homes, offices, communities, and laboratories. The company is distinguished by its cutting-edge application laboratory, research and development center, customer support service centers, and manufacturing facilities that comply with ISO 9001 and ISO 14001 standards. Among its innovations, the INDION LabQ range water purification system stands out, delivering multiple grades of pure and ultrapure water for both routine and critical laboratory applications. With features like the Automatic Flush Device (AFD), Integrated Recirculation System, and optional filtration, it ensures compliance with regulations and offers competitive pricing.

High Purity Water For Semiconductor & Electronics Industry

In the electronics industry, where precision is paramount, the quality of water plays a critical role, especially in processes involving pure and ultra-pure water for cleaning electronic components like semiconductors and flat panel displays. Ion Exchange offers an extensive range of water treatment systems tailored to meet these stringent requirements, including solutions like distilled water and pure water distillers. Beyond that, Ion Exchange also provides advanced wastewater treatment and recycling systems, helping reduce freshwater usage and enabling resource recovery, ensuring sustainable and efficient water management across the industry.

Conclusion

The benefits and uses of distilled water across various industries in Sri Lanka are vast and significant. From pharmaceuticals to electronics, food, and beverage to automotive, distilled water ensures product quality, safety, and efficiency by providing a contaminant-free medium. The future of distilled water applications is promising, with advancements in distillation technology continuing to enhance its purity and availability. The importance of water purity in industrial processes cannot be overstated, as it directly impacts the final product’s quality and reliability.