Sri Lanka’s automotive sector—covering vehicle assembly, component manufacturing, maintenance workshops, and service stations—generates significant volumes of oily wastewater. This wastewater typically contains lubricants, greases, emulsified oils, detergents, heavy metals, and suspended solids. Discharging such effluent without proper treatment can severely impact waterways, soil, and public health.

To meet environmental regulations and sustainability goals, automotive facilities are increasingly turning to membrane filtration—a high-performance technology that enables efficient oil-water separation, reuse of treated water, and consistent regulatory compliance.

What Is Membrane Filtration in Water Treatment?

To understand its value, it is important to clarify what membrane filtration water treatment. Membrane filtration is a physical separation process where wastewater is passed through a semi-permeable membrane that selectively allows water molecules to pass while retaining oil, solids, and contaminants.

Unlike conventional methods that rely heavily on gravity separation or chemical treatment, membrane systems provide precise and repeatable performance—even for emulsified oils that are difficult to remove through traditional processes.

Oily Wastewater Challenges in Sri Lanka’s Automotive Industry

Automotive operations in Sri Lanka face several wastewater treatment challenges:

- Emulsified Oils from detergents and high-pressure washing

- High COD and TSS Levels from machining, washing, and floor cleaning

- Variable Flow and Contaminant Load across workshops and plants

- Strict Environmental Norms for discharge into surface water and municipal systems

- Rising Water Costs, making reuse increasingly attractive

Conventional oil traps and chemical treatments often fail to consistently meet discharge standards or enable reuse. This is where advanced membrane filtration techniques provide a reliable solution.

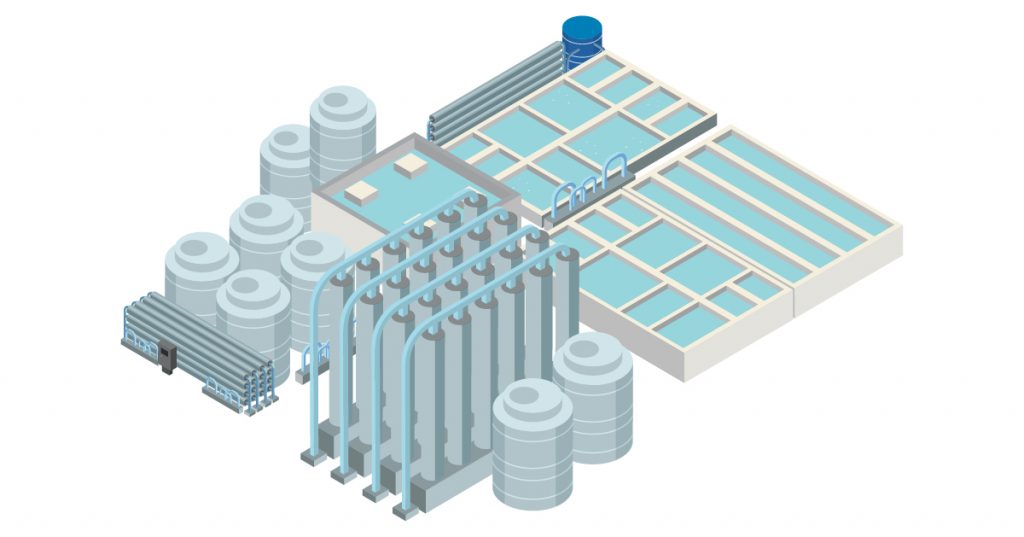

The Membrane Filtration Method for Oily Wastewater

The membrane filtration method works through a multi-stage process designed to protect the membrane while maximizing oil and contaminant removal:

1. Pre-Treatment

Coarse screens, oil skimmers, and equalization tanks remove large solids and free-floating oil, stabilizing the influent.

2. Membrane Filtration Unit

The heart of the system is the membrane filtration unit, typically using ultrafiltration (UF) or microfiltration (MF). As wastewater flows through the membrane, oils, grease, suspended solids, and colloids are retained, while clean water permeates through.

3. Polishing and Reuse

Depending on reuse requirements, treated water can be further polished using reverse osmosis or carbon filtration before being reused for:

- Vehicle washing

- Cooling systems

- Floor cleaning and utilities

This membrane filtration technique enables high recovery of water while minimizing sludge generation.

Membrane Filtration Materials: Built for Performance

The efficiency and durability of any system depend on the membrane filtration materials used. High-quality membranes are typically manufactured from polymers such as PVDF, PES, or ceramic materials that offer:

- Strong resistance to oil and chemicals

- High mechanical strength

- Long service life with minimal fouling

- Ease of cleaning and maintenance

Ion Exchange carefully selects and integrates membrane materials that deliver consistent performance under the challenging conditions of automotive wastewater.

Why Membrane Filtration Is Ideal for Automotive Facilities in Sri Lanka?

Implementing membrane-based treatment offers several advantages:

- High Oil Removal Efficiency – Effectively treats both free and emulsified oils

- Compact Footprint – Ideal for space-constrained workshops and plants

- Water Reuse Capability – Reduces freshwater consumption and operating costs

- Regulatory Compliance – Ensures effluent meets discharge and reuse standards

- Lower Sludge Generation – Compared to chemical coagulation methods

With growing environmental scrutiny and water scarcity concerns, membrane systems provide a future-ready approach for Sri Lanka’s automotive sector.

Ion Exchange’s Expertise in Membrane Filtration Solutions

Ion Exchange has decades of experience in designing and delivering advanced membrane filtration units for industrial wastewater treatment across Asia. Our solutions for oily wastewater are engineered for reliability, efficiency, and long-term sustainability.

Bio-diesel manufacture & purification

Various kinds of oil – palm, corn, rapeseed, etc. – are used as feedstock in the manufacture of bio-diesel. Typically, such oils contain high triglycerides and free fatty acids (FFA). The use of our ion exchange resin in bio-diesel manufacture and purification improves conversion of feedstock into finished product and consequently the cost-effectiveness of the process, and results in high purity of the end product. It is also more eco-friendly as it eliminates the use of sulphuric acid as well as substantially reduces water consumption and therefore, the generation of wastewater.

Oily waste treatment in the auto industry

Automobile-component manufacture uses significant quantities of metal-working fluids. These oil-water emulsions are used in precision machining, for lubrication, cooling, cleaning, etc., and therefore metal-working facilities generate large amounts of oily wastewater. Water scarcity and stricter disposal regulations have resulted in an increasing trend towards water reuse, and away from conventional physico-chemical treatment processes, which increase TDS levels in the effluent, making it difficult to treat. Thus, membrane filtration is now playing a prominent role in the treatment of oily wastes because of its many advantages: chemical additives are not required to destabilise the emulsion, high COD removal efficiencies are achieved, and treatment systems are quite compact, automated,d and easy to operate. Additionally, membrane permeate can be reused as make-up water for emulsification or discharged directly into a receiving water body.

The Future of Automotive Wastewater Management in Sri Lanka

As Sri Lanka’s automotive industry modernizes, sustainability will be a key differentiator. Water reuse, environmental compliance, and cost efficiency will increasingly shape operational decisions. Membrane filtration stands at the forefront of this transformation—enabling industries to move beyond basic treatment toward circular water management.

Conclusion

Advanced membrane filtration is redefining how the automotive industry in Sri Lanka treats oily wastewater. By applying the right membrane filtration method, selecting robust membrane filtration materials, and deploying efficient membrane filtration units, facilities can achieve superior oil removal, reduce freshwater consumption, and meet stringent environmental standards.

With Ion Exchange’s proven expertise in membrane filtration techniques and industrial water treatment, automotive manufacturers and service operators can confidently adopt sustainable wastewater solutions—protecting both their operations and the environment.