Clean and safe water is essential for health and well-being, yet access to such water remains a challenge in many parts of the world, including Sri Lanka. With increasing pollution and the rising demand for water resources, adopting advanced water treatment methods has become crucial. One of the most effective technologies used today is ultrafiltration. This method has revolutionized water purification by offering efficient removal of contaminants while maintaining essential minerals.

In this blog, we’ll explore what ultrafiltration is, how ultrafiltration membranes work, and its role in water treatment systems in Sri Lanka.

What Is Ultrafiltration?

Ultrafiltration is a water purification process that uses a semi-permeable membrane to remove contaminants from water. The ultrafiltration membrane acts as a barrier that filters out particles, bacteria, viruses, and other impurities while allowing water and smaller molecules to pass through. This process does not rely on chemicals and operates under low pressure, making it both eco-friendly and energy-efficient.

Unlike traditional filtration methods, ultrafiltration can remove impurities as small as 0.01 microns. This makes it particularly effective for treating water with high levels of suspended solids, turbidity, and microbial contamination, which are common issues in Sri Lanka due to agricultural runoff, industrial waste, and untreated sewage.

How Does Ultrafiltration Work?

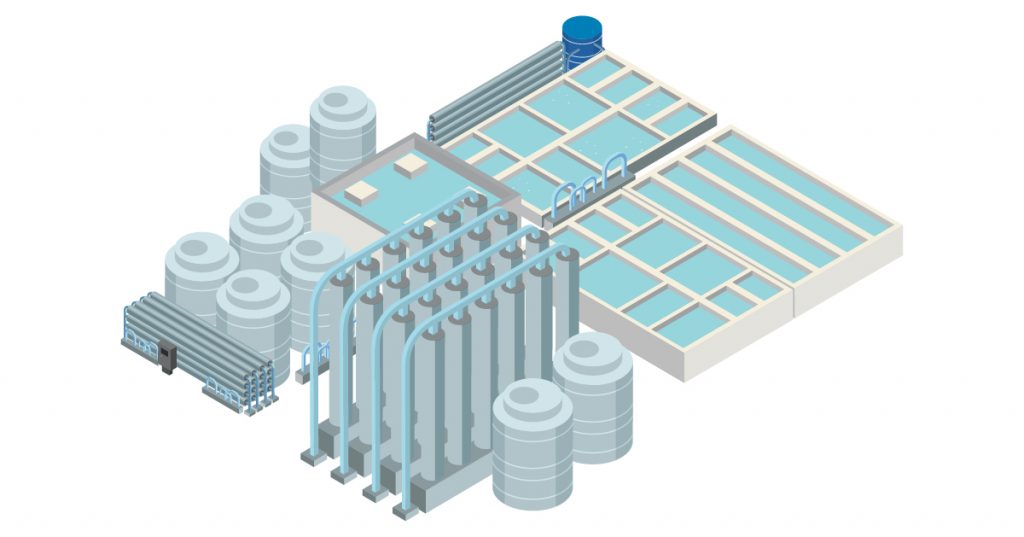

Ultrafiltration operates through a simple yet highly effective mechanism:

- Pre-Treatment: Before water enters the ultrafiltration system, it often undergoes pre-treatment to remove large debris and reduce the load on the ultrafiltration membrane. This step ensures the system operates efficiently and extends the membrane’s lifespan.

- Filtration: Water passes through the ultrafiltration membrane under low pressure. The membrane’s pores, which are smaller than bacteria and most viruses, allow only clean water and small dissolved molecules to pass through while blocking contaminants like suspended solids, microorganisms, and certain organic compounds.

- Backwashing and Cleaning: Over time, the ultrafiltration membrane accumulates contaminants on its surface. Regular backwashing and chemical cleaning remove these deposits, restoring the membrane’s performance and ensuring consistent water quality.

- Post-Treatment: After ultrafiltration, water may undergo additional treatments such as disinfection or reverse osmosis, depending on the intended use. However, ultrafiltration alone is sufficient for many applications, including drinking water, industrial processes, and wastewater recycling.

Types of Ultrafiltration Membranes

The effectiveness of ultrafiltration largely depends on the type of ultrafiltration membrane used. These membranes are categorized based on their material and configuration:

-

Material:

-

- Polymeric Membranes: Made from materials like polysulfone or polyethersulfone, polymeric membranes are lightweight, cost-effective, and commonly used in water treatment systems.

- Ceramic Membranes: These are made from materials like alumina or zirconia. They are more durable and resistant to high temperatures and harsh chemicals but are generally more expensive.

- Polymeric Membranes: Made from materials like polysulfone or polyethersulfone, polymeric membranes are lightweight, cost-effective, and commonly used in water treatment systems.

-

Configuration:

- Hollow Fiber Membranes: These membranes consist of thin, hollow fibers and are widely used due to their high surface area and ability to handle large volumes of water.

- Flat Sheet Membranes: These membranes are used in plate-and-frame or cassette systems and are suitable for smaller-scale applications.

- Tubular Membranes: These membranes are used in applications where water contains high levels of suspended solids, as they are less prone to fouling.

- Hollow Fiber Membranes: These membranes consist of thin, hollow fibers and are widely used due to their high surface area and ability to handle large volumes of water.

Applications of Ultrafiltration in Sri Lanka

Ultrafiltration is increasingly being adopted in Sri Lanka for various applications, including:

- Drinking Water Treatment: Sri Lanka faces challenges related to contaminated drinking water sources, particularly in rural areas. Ultrafiltration systems effectively remove bacteria, viruses, and turbidity, providing safe and clean drinking water.

- Industrial Water Treatment: Industries in Sri Lanka, such as textiles, food and beverage, and pharmaceuticals, require high-quality water for their operations. Ultrafiltration ensures consistent water quality by removing impurities, thus improving product quality and reducing equipment maintenance costs.

- Wastewater Recycling: With water scarcity becoming a pressing issue, ultrafiltration is being used to recycle wastewater for non-potable applications like irrigation, cleaning, and cooling. This helps industries and municipalities conserve freshwater resources.

- Desalination Pre-Treatment: For coastal areas where desalination is a viable solution, ultrafiltration is used as a pre-treatment step to remove suspended solids and protect reverse osmosis membranes from fouling.

- Community Water Supply Systems: In areas affected by natural disasters or where infrastructure is limited, ultrafiltration systems provide an efficient and portable solution for delivering clean water to communities.

Meeting Sri Lanka’s Water Treatment Needs with Ion Exchange

Ion Exchange is a leading provider of water treatment solutions in Sri Lanka, offering a range of ultrafiltration systems designed to meet the diverse needs of its clients. The company’s expertise in water treatment ensures that each ultrafiltration system is tailored to the specific requirements of the application, whether it’s for residential, commercial, or industrial use.

HYDRAMEM – Ultrafiltration Membrane

It is a tangential flow, a pressure-driven process that effectively filters particles based on their molecular size. With pore diameters ranging from 10 to 200 Å (0.001 to 0.02 microns), ultrafiltration membranes allow solvents and smaller species to pass through, resulting in a purified ultrafiltrate known as permeate, while larger particles are retained and concentrated. These membranes are reusable and can be cleaned with standard chemicals, making them highly efficient for continuous use. Ultrafiltration in process water treatment ensures the removal of nearly all particulate matter, suspended solids, bacteria, viruses, pyrogens, and colloidal materials, including non-reactive silica, iron, aluminum, and high molecular weight organics, making it essential for pharmaceutical and industrial applications.

Conclusion

Ultrafiltration is a highly effective water treatment technology that has found widespread application in Sri Lanka due to its numerous benefits. From providing high removal efficiency of contaminants to offering energy efficiency and low operational costs, ultrafiltration addresses the country’s water quality challenges. As Sri Lanka continues to grapple with water scarcity and the need for sustainable solutions, ultrafiltration offers a promising pathway toward ensuring safe, clean, and reliable water supplies. Whether for urban, rural, agricultural, or industrial use, ultrafiltration membranes play a crucial role in supporting Sri Lanka’s water treatment needs.

Connect with Ion Exchange experts today to learn more about ultrafiltration and how it can be applied in your specific situation.